Integrate for production

Обзор

SINUMERIK Integrate for production

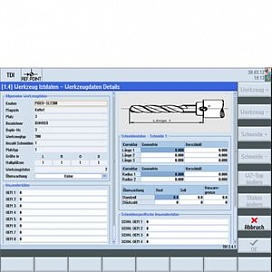

Manage CNC programs | Manage MyPrograms |

Manage tools | Manage MyTools |

Record machine states | Analyze MyCondition |

Perform remote maintenance | Access MyMachine /Ethernet |

Enable data access | Create MyInterface |

Archive machine data | Access MyBackup |

Note:

Access MyBackup is an interface which enables Solution Partners to offer their own products in the field of archiving systems on this basis. The certified SINUMERIK Solution Partners are the companies Auvesy and MDT Software.

More efficient production through intelligent IT integration

Siemens makes the complete range of IT integration available as an expansion of its CNC technology SINUMERIK 840D sl. This increases productivity in service and production, and expands the automation of the production. Machines communicate with higher-level control systems, and simply have to be expanded by new functionality. On the way toward the digital factory, the SINUMERIK Integrate product family offers productive solutions for integrating IT into production facilities.

There is potential for increasing the productivity of CNC manufacture by networking machines and plants. This requires production data to be collected and evaluated transparently. Siemens offers SINUMERIK Integrate as a central platform, that provides useful modules for analyzing and managing data for individual machines and networked plants.

Future-proof investment in scalable software

Investment protection and future security with SINUMERIK Integrate

A typical production environment lasts for several years or even decades. In this time, the IT infrastructure is subject to continual change, whereas the machines remain virtually unchanged. At the same time, new requirements frequently arise, that can be met by expanding the software functionality – if possible without changing the machine-related software. SINUMERIK Integrate for production enables resources to be networked and processes and production data to be centrally managed. The security of the data is ensured from end to end. On the one hand by encrypted data transport and, on the other hand, because the machines can be operated with completely isolated firewalls.

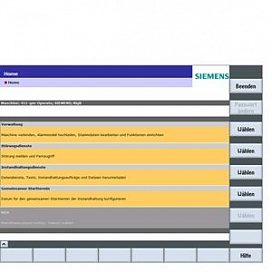

Scalable stand-alone and client-server solutions

SINUMERIK Integrate for production is a client-server solution that is typically used in the environment of a local or decentralized machine park. Individual SINUMERIK Integrate applications can also be used as local solutions in the environment of a single machine. After installation, SINUMERIK controlled machines can be easily integrated as clients in an IT network on the Integrate Server with the user interfaces HMI Advanced or SINUMERIK Operate. The entire software package comes from a single source, individual applications are activated by a simple installation and licensing procedure. The system is thus easily scalable.

The link to company level

SINUMERIK Integrate for production enables machine tools to be easily networked into higher-level production IT systems. The software runs directly on the CNC, records all the data from the CNC and PLC, and makes it available for further use.

If the machines are connected to the server, new functions can be easily copied onto them. This is where the standardization of the Siemens portfolio pays off, as PLM and MES systems can be easily connected to increase productivity still further. This ensures cost advantages in both procurement and operation.

A platform with many advantages

SINUMERIK Integrate for production is a central platform with which the productivity of the end user or the service of machine manufacturers can be increased, and the automation of production expanded. Optimizing the production enables, on the one hand, more parts to be produced and, on the other hand, errors, such as missing tools, incorrect CNC programs, as well as high energy consumption, and material and tool inventories to be reduced.