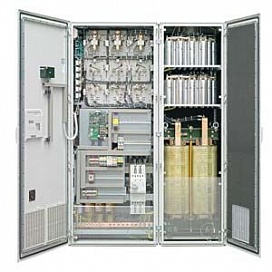

LOHER DYNAVERT I Current-source Inverters

Обзор

LOHER DYNAVERT I Current‑Source Inverters

General description

LOHER DYNAVERT I drive units are currentsource DC link inverters that are used to control induction motors. They have a fully controlled B6 bridge circuit on the line side and a B6 inverter circuit on the output side, which utilizes the principle of interphase commutation; this distributes the DC link current from the DC link reactors with a square waveform with frequency f to the motor winding. As a consequence, the motor cable length is almost unlimited.

The power flows from the line supply to the motor for a motoring load. For regenerative operation, the rectifier on the line-side feeds the regenerated energy back into the line supply. This means that from the inherent principle, 4‑quadrant operation is possible without requiring any additional measures. 12- and 24‑pulse versions further reduce the harmonics fed back into the line supply. For this reason LOHER DYNAVERT I is the ideal replacement for SIMOVERT A.

Features

Explosion protection

- ATEX‑certified for motors located in hazardous zones with Accessory kit S, also with very long motor cable length

Emergency Off

- The Emergency Off function prevents unexpected starting in compliance with EN 60204‑1, implemented according to EN 954‑1, Category 3, respectively SIL2 with Accessory kit S

Power unit

- 12- and 24‑pulse input optional posible. For this reason gi line supply (basic fundamental) of 99.9 % is possible

- This corresponds to the EMC Directives (EN 61800‑3 environment 2) as a result of the line filter integrated as standard

- Low harmonics fed back into the line supply as a result of the integrated line reactor

- Long motor cable lengths possible inherent to the system

- Insulation monitoring for IT line supplies for 500 V/690 V drive units as well as ground fault monitoring for TN and TT line supplies integrated in the 400 V drive units

- Wide supply voltage range

- Normal fuses can be used for protection (gL characteristic)

Control section

- High level of personnel and plant protection through protective separation between the analog and digital control peripheral and the power unit according to VDE 0106/EN 50178

Operator control and setting

- Transparent operator control and setting using a menu-prompted 4‑line plain text display with membrane keypad at the drive inverter – or up to 1000 m away in the main control room via RS485

- Extensive functions using the Windowsbased PC operator control program

Communication

- Communication via a conventional terminal strip with freely‑programmable digital and analog inputs/outputs, with

- parameterizable limit value signals

- parameterizable timers

- parameterizable damping elements

- parameterizable drive inverter behavior when inputs/outputs respond

- Communication and parameterization via

- PC using IMS (Inverter Management Software) via RS232/RS485

- external operator panel via RS485

- bus systems such as Profibus DP or Modbus RTU

Drive behavior for LOHER DYNAVERT I

- Two closed‑loop control types for induction motors:

- Speed control

- Torque control

- Full 4‑quadrant operation with regenerative braking as standard

The following generally apply

- Automatic slip compensation

- Stall protection using current limiting control

- Flying restart circuit to connect to a rotating motor